Another weekend, another update. I'm getting into a rhythm here.

Another weekend, another update. I'm getting into a rhythm here.

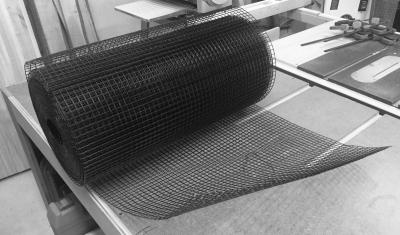

This weekend's goal was to build the front and side doors. Unlike the main structure, which is out of southern yellow pine (SYP), I'm building the doors out of whitewood, which is significantly lighter. I don't want the doors to sag.

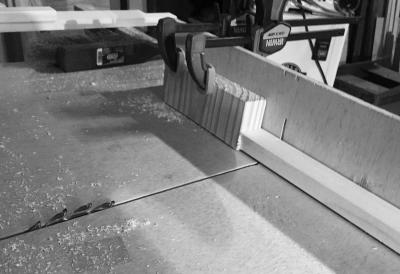

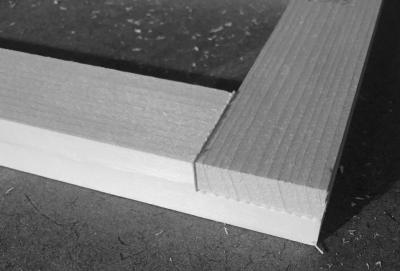

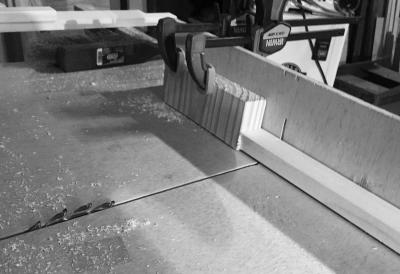

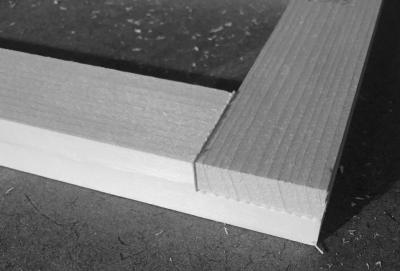

I ripped an 8' 2x6 down into 1" by 1 ½" strips on the table saw, then cut them to length on the chopsaw. The plan is to half-lap the corners for strength. The doors should be light enough, even with the cage material attached, to stay square. I set up the crosscut sled on the table saw to cut the half-laps. This took some dialing-in. I set it up for less than half the depth and then inched up on the correct fit. I didn't bother installing the dado stack, I just nibbled away with multiple cuts. (AKA, 'The I'm too lazy to set it up' method, or better known as the Norm Abrams method.) Here, you can see that the depth is *not quite* deep enough. Another half-turn on the blade height knob and it was perfect. I also tweaked the location of the stop block a touch to make the overlap perfectly square.

I ripped an 8' 2x6 down into 1" by 1 ½" strips on the table saw, then cut them to length on the chopsaw. The plan is to half-lap the corners for strength. The doors should be light enough, even with the cage material attached, to stay square. I set up the crosscut sled on the table saw to cut the half-laps. This took some dialing-in. I set it up for less than half the depth and then inched up on the correct fit. I didn't bother installing the dado stack, I just nibbled away with multiple cuts. (AKA, 'The I'm too lazy to set it up' method, or better known as the Norm Abrams method.) Here, you can see that the depth is *not quite* deep enough. Another half-turn on the blade height knob and it was perfect. I also tweaked the location of the stop block a touch to make the overlap perfectly square.

A

A fter cutting the joints, I then went back and touched them up with a sharp bench chisel to remove any loose cruft between adjacent 'nibbles'. This also smoothed the cheeks of the inside joint enough that the glue joint should be strong. I glued up all of the doors and allowed them to dry for about three hours.

fter cutting the joints, I then went back and touched them up with a sharp bench chisel to remove any loose cruft between adjacent 'nibbles'. This also smoothed the cheeks of the inside joint enough that the glue joint should be strong. I glued up all of the doors and allowed them to dry for about three hours.

I'm using the quick clamps for everything these days, since most of my nicer clamps are all still packed away in a box somewhere. The sad part about that is that I built a really nice wall-mounted clamp rack for all of my clamps back in Florida, but I just don't have the wall space in this shop to put it up. (Not that I want to drill any more holes in the rented walls in any case.)

Got a bit more done on the aviary tonight. I bought the basic door hardware from the big box hardware store last weekend and finished installing it today. The hinges I had on already, but I've now installed the door latches, the door handles, and the knobs on the little doors. These knobs were actually in a box in the house we had in Florida. That home had been built by the builder of the development, and I found a box of about a hundred white ceramic knobs and mounting screws. I've used the heck out of those knobs over the years. I've only got a few left. Here I mounted two on the little side doors of Adriana's aviary.

Got a bit more done on the aviary tonight. I bought the basic door hardware from the big box hardware store last weekend and finished installing it today. The hinges I had on already, but I've now installed the door latches, the door handles, and the knobs on the little doors. These knobs were actually in a box in the house we had in Florida. That home had been built by the builder of the development, and I found a box of about a hundred white ceramic knobs and mounting screws. I've used the heck out of those knobs over the years. I've only got a few left. Here I mounted two on the little side doors of Adriana's aviary.

My site here had a rough patch the last few days. I attempted an update to the content management system, which caused problems. But then backing out of that update caused the whole site to go down. I should know, working in IT, to depend on things going well when you upgrade. Luckily, I do have good backups. And we're back up and running now.

My site here had a rough patch the last few days. I attempted an update to the content management system, which caused problems. But then backing out of that update caused the whole site to go down. I should know, working in IT, to depend on things going well when you upgrade. Luckily, I do have good backups. And we're back up and running now.